Premier Aluminum Llc Things To Know Before You Buy

Premier Aluminum Llc Things To Know Before You Buy

Blog Article

10 Simple Techniques For Premier Aluminum Llc

Table of ContentsThe Facts About Premier Aluminum Llc RevealedUnknown Facts About Premier Aluminum LlcThe smart Trick of Premier Aluminum Llc That Nobody is DiscussingThe Best Strategy To Use For Premier Aluminum Llc

(https://justpaste.it/1zrj7)Traditionally, a buyer's key duty was to locate professional and receptive providers. In some cases, buyers presumed that any type of supplier going to contractually fulfill the purchase requirement was certified. Using reduced price and unqualified distributors can trigger top quality concerns, and lost time and money in the lengthy run. To assist you via the process, below are some points to take into consideration when selecting the ideal metal casting distributor.

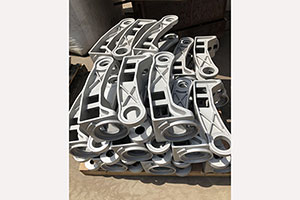

A company that just makes use of the investment casting procedure will try to sell you on why that procedure is best for your application (Foundry). What if utilizing the sand casting process is best for you and your needs? Rather, seek a supplier that supplies a variety of casting processes so the finest option for YOU is picked

If collaborating with a single resource for every one of your casting needs is necessary to you, the supplier requires to be varied in its capacities. When incorporated with other integrated capabilities, this can assist simplify and compress the supply base. When picking the appropriate spreading provider, cautious consideration must be offered to top quality, solution, and price.

The smart Trick of Premier Aluminum Llc That Nobody is Discussing

Purchasers increasingly select casting suppliers that have machining capacities. If the casting supplier discovers an issue during machining, the problem is resolved faster with no dispute over whose fault it is.

What do you need from your spreading supplier? Are you looking for a person to simply deliver a steel part to your front door or do you need extra?

Some foundries are limited or specialized. Make sure the distributor can fulfill all your product or alloy requirements to get rid of the demand for multiple vendors.

Some Ideas on Premier Aluminum Llc You Should Know

Research the vendor's site. Talk to a sales representative or company associate. Ask a great deal of concerns. Visit their center. Obtain an understanding of what they can do for you why not check here and if you can see yourself constructing a solid, shared partnership with them.

Aluminum is additionally lightweight and has excellent deterioration resistance, making it excellent for applications where weight and resilience are necessary variables. In addition, aluminum casting is a cost-efficient approach of manufacturing, as it needs less energy and sources than other approaches. Iron casting, on the other hand, entails pouring liquified iron right into a mold to produce a wanted form.

A Biased View of Premier Aluminum Llc

Iron spreading is additionally able to endure high temperature levels, making it ideal for usage in applications such as engine parts and industrial equipment. Nevertheless, iron spreading can be more costly than light weight aluminum casting as a result of the greater cost of basic materials and the energy called for to thaw the iron. When choosing between light weight aluminum casting and iron casting, it is important to think about the certain requirements of the application.

In conclusion, both light weight aluminum casting and iron spreading have their own distinct benefits and downsides. There are three sub-processes that drop under the category of die spreading: gravity die spreading (or permanent mold and mildew casting), low-pressure die spreading and high-pressure die casting. To obtain to the finished item, there are three main alloys used as die spreading material to choose from: zinc, light weight aluminum and magnesium. Report this page